charpy impact testing standards|charpy impact test sample : commercial The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod. For the test, a notched metal specimen is broken in half using a pendulum hammer.

Encuentra los salmos para ganar la lotería adecuados para tus objetivos. Crea un ambiente propicio para la meditación y la oración. El poder del salmo 145 (salmos para ganar la lotería) SALMO 145; Repite los .

{plog:ftitle_list}

E Premiere - Assine Globoplay

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If .The Charpy impact test is performed to evaluate the resistance of plastics to breakage by flexural shock according to standard test method ASTM D6110 [7]. It indicates the amount of energy .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.

4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specificationsThe ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod. For the test, a notched metal specimen is broken in half using a pendulum hammer.ISO 148-1:2016 specifies the Charpy (V-notch and U-notch) pendulum impact test method for determining the energy absorbed in an impact test of metallic materials. This part of ISO 148 .ISO 179-1:2010 specifies a method for determining the Charpy impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are .

The four most common impact-test procedures in use around the world are probably ISO 148 “Steel— Charpy impact test V-notch ,” ASTM E 23 “Standard Test Methods for Notched Bar .Standards • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials Purpose . translates into the toughness of the material. Equipment and Materials • Charpy V-notch impact testing machine (figure 1.3.1) • Specimens: 1018 CR steel & 6061-T6 aluminum • Thermometer • Water • Dry ice • Hot plate • Oven . 5.4 For tough, ductile, fiber-filled, or cloth-laminated materials, the fracture propagation energy is usually large compared to the fracture initiation energy. When testing these materials, energy losses due to fracture propagation, vibration, friction between the striking nose and the specimen has the potential to become quite significant, even when the specimen is .

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .This standard was first published in 1961 and subsequently revised in 1973. In this revision the standard has been brought in line with IS0 148-1988 ‘Steel - Charpy impact test ( V-notch )‘, issued by the fnternational Organizetion for Standardization (ISO). 4 Printed rt New India Rinti~ Pmr Khwjr, India 1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .

A Charpy impact testing apparatus, a device with a pendulum with various locking points at specified heights and a fixture to hold the test specimen, is used to determine Charpy impact strength. The standard test specimen is described in ASTM E23. It has a V-shaped notch cut into it. It is oriented so that it is simply supported on both ends .4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications. 5 Information to be gained from the impact test. . ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO member bodies). The work of preparing International Standards is normally .For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If your focus is on plastics or polymers, the Charpy Izod Pendulum Impact Tester for Plastics is perfect for assessing the toughness of non-metal materials. Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. . The testing standard will also dictate how many samples must be tested. Measure Sample: The sample must be accurately measured with a vernier .

charpy test sample dimensions

The standards ISO 179-1 (non-instrumented impact strength test) and ISO 179-2 (instrumented impact strength test) describe the Charpy impact test for determination of the impact characteristics (impact strength and notched impact strength) of plastics. Impact tests to Charpy are also described in the ASTM D6110 standard.Engineers and researchers who have specialized Charpy testing needs will be the primary users of two new standards recently approved by ASTM International Committee E28 on Mechanical Testing. The new standards, E2248, Test Method for Impact Testing of Miniaturized Charpy V-Notch Specimens, and E2298, Test Method for Instrumented Impact Testing of Metallic . Charpy impact test standards. ASTM E23, ASTM D6110, ASTM A370, ASTM D256. ISO 13479, ISO 148-1. EN 10045-1, EN ISO 179-1 Izod impact testing. While Charpy impact testing is widespread for metals, Izod impact testing is more often used for plastics and other softer materials. In Izod testing, the notched specimen is positioned vertically instead .CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the . The standard test for ASTM D256 requires specimens to be made with a milled notch. This is technically an equivalent standard to ISO 180 – Determination of Izod Impact .

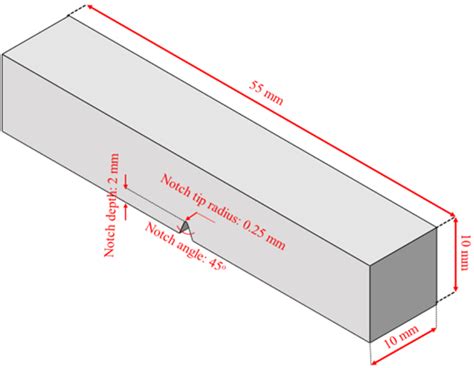

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after .

Charpy impact strength Charpy notched impact strength a cU (a cN) impact energy at break (3.10) relative to the initial central cross-sectional area A (A N) of the unnotched (notched) specimen Note 1 to entry: It is expressed in kilojoules per square metre (kJ/m2). Note 2 to entry: See 8.4 and ISO 179-1:2010, 3.1 and 3.2. 3.12 type of failure BMany notched bar impact tests of different designs and loading have been used to predict brittle fracture of ferritic steels. In the USA, the Charpy specimen has been standardized in ASTM E23 for impact three-point bend testing (ASTM E23 1999).Figure 1 illustrates a standard ASTM type A Charpy impact test specimen. The Charpy three-point bend specimen is more convenient .

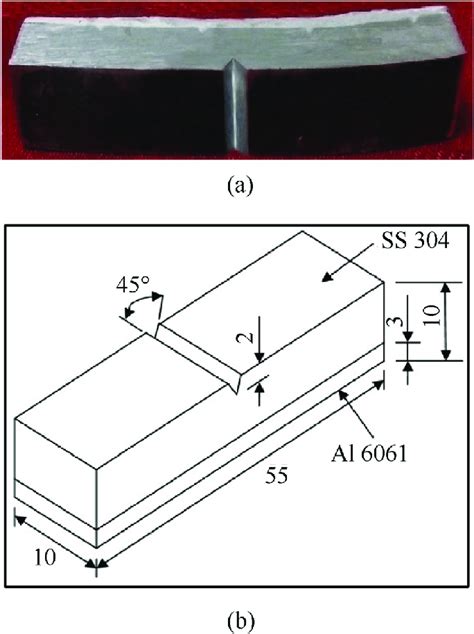

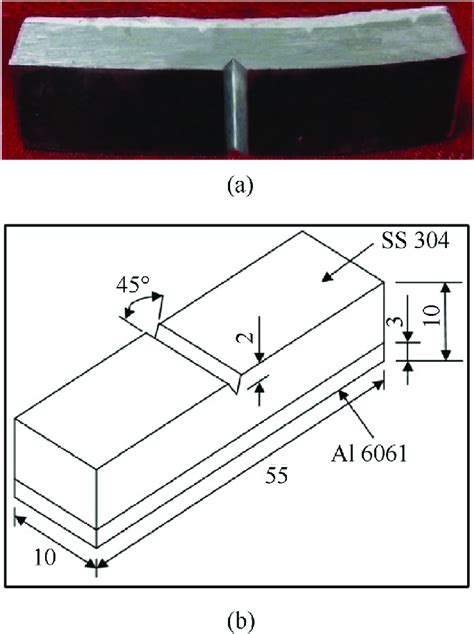

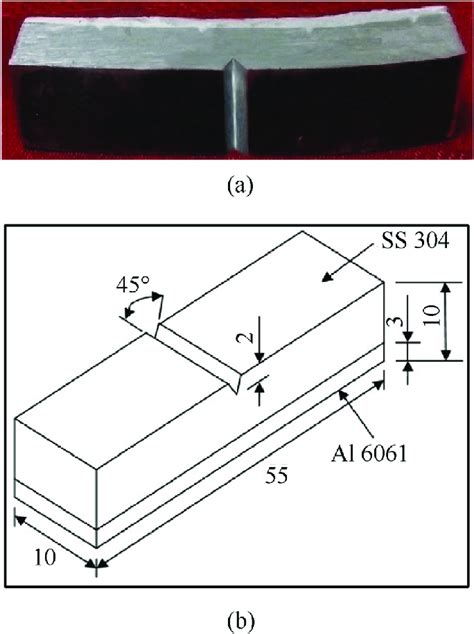

The standard Charpy Impact Test specimen consist of a bar of metal, or other material, 55x10x10mm having a notch machined across one of the larger dimensions. V-notch: 2mm deep, with 45° angle and 0.25mm radius along the base; U-notch and keyhole notch: 5mm deep notch with 1mm radius at base of notch; The Charpy Impact Test consist of striking .Charpy Impact Test ISO 179. Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken.

.the right impact test equipment for standard-compliant testing! Impact testers help determine the failure behavior of materials or components under rapid loads and changing temperatures. Because many materials used for a number of different applications on a daily basis are subjected to fluctuating temperatures, and since the fracture or failure behavior also depends on .

ISO 148-1:2016 specifies the Charpy (V-notch and U-notch) pendulum impact test method for determining the energy absorbed in an impact test of metallic materials. This part of ISO 148 does not cover instrumented impact testing, which is specified in ISO 14556.

The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic impacts. Even as businesses change, the Charpy impact test is still a valuable and essential tool.Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens.According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant

Metallic materials — Charpy pendulum impact test — Part 1: Test method 1 Scope This part of ISO 148 specifies the Charpy (V-notch and U-notch) pendulum impact test method for determining the energy absorbed in an impact test of metallic materials. This part of ISO 148 does not cover instrumented impact testing, which is specified in ISO 14556.Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values obtained can be used for quality control or to differentiate general toughness. Test Procedure:

The standard size of a specimen for Charpy impact testing is 10 mm × 10 mm × 55 mm. A 2mm deep notch with an angle of 45° and a tip radius of 0.25mm is then machined into one face of the bar. These specifications have a very tight tolerance because the shape and size of the notch can have a significant effect on the results of the test.

Artificial Light Color Fastness Tester distribution

charpy impact test standard pdf

Resultado da Reload page. 4,222 Followers, 509 Following, 489 Posts - See Instagram photos and videos from SOFASCORE DO LEÃO | SPORT 🦁 .

charpy impact testing standards|charpy impact test sample